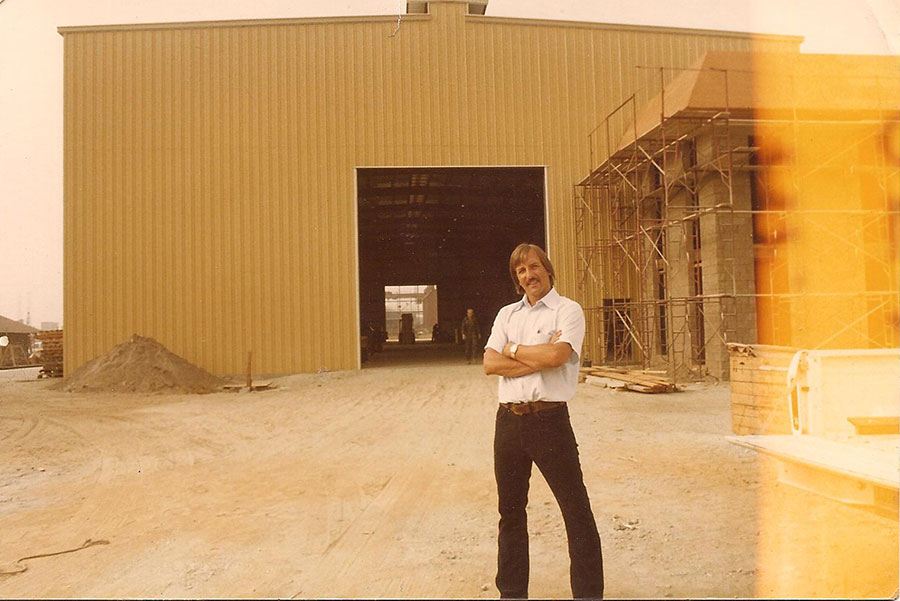

Jeff Carlton founded Press Forge in 1978 and served as the company’s Chairman and CEO until his passing September 24, 2012.

From our modest beginnings as a forger of elevator links for oil field use, we have grown to become the largest converter of customer owned inventory in the country. In 2014 our employees processed over 32 million pounds of titanium, steel, and high temp alloys in billet, bar, slab, and shape forgings to our customers’ exact specifications.

Our goal is to provide you with the most cost effective manufacturing path to produce your final product. We focus on minimizing yield loss which, next to the actual ingot cost itself, is typically your greatest cost of conversion.

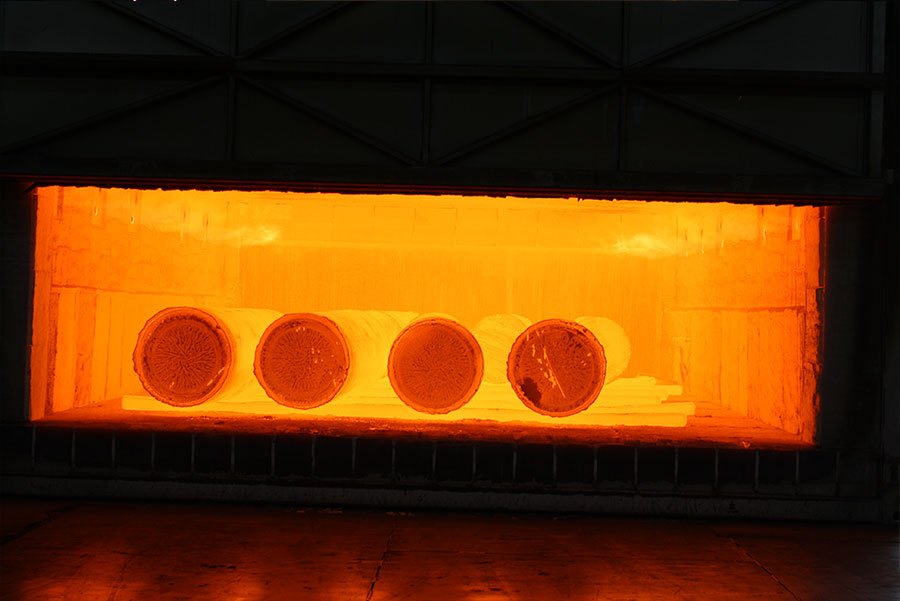

With four open-die presses we are capable of handling material up to 30,000 pounds and processing billet lengths to 30 feet. Longer billet lengths mean fewer pieces and less end loss, improving your yield and lowering your total product cost.

Press Forge can stock your billet and ingot at our facility, enabling us to respond very quickly to your requests, regardless of how small or large the quantity of your order. Additionally, our equipment and facilities are well diversified and highly flexible enabling us to offer a wide range of forged product forms and sizes.

Press Forge Timeline

| New rolling mill commissioned for near net shape rectangular forgings | 2015 |

| 2012 | 1,100 ton press commissioned for additional capacity |

| Replacement billet grinder commissioned | 2011 |

| 2011 | 1st electronically controlled air/gas ratio furnace |

| 3rd billet grinder Installed for 30ft capacity | 2011 |

| 2009 | 3 acre parcel purchased to bring total to 8 acres |

| 3,000 ton press commissioned for additional capacity | 2008 |

| 2008 | 15 ton mobile manipulator added |

| State-of-the-art electronic controls added to open die | 2004 |

| 1997 | Surpassed 10 million pounds processed annually |

| 2nd billet grinder installed | 1997 |

| 1994 | 1st billet grinder installed |

| 1,500 pon press commissioned for ingot breakdown | 1982 |

| 1978 | 750 ton press commissioned |

| Press Forge incorporated | 1978 |